Our Products

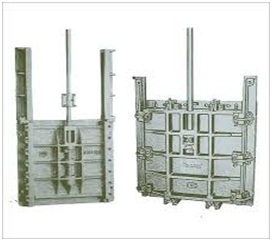

CAST IRON SLUICE GATES AS PER IS: 13349 OR AWWA-C560 OR BS: 7775+

Introduction

This is a rectangular Sluice Gate suitable for Wall mounting with unseating head up to 30 Meter and off seating head up to 20 Meter as standard with modification higher head is also available.

Benifetes and Features

- This Sluice Gate is very robust and can be mounted on pipe flange, wall with flange back or flat back mounted with or without thimble. Due to wall thimble is grouted in concrete. This gate can be easily mounted and dismounted with nut bolts fitted on thimble.

- This sluice gate is used where least leakages are desired. This gate gets verified at shop for the desired water pressure on wall for actual leakages as per quality standards..

- F type or E type wall thimble can be used as per requirement.

- Adjustable wedges with non corrosive wedge plates helps to seal the faces.

- Stem guide is provided if the operating height is more than 2 Mts. the gate height along with the couplings if required.

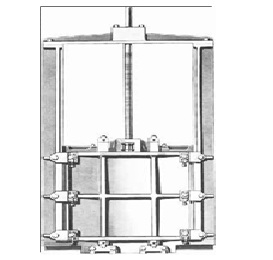

CAST IRON SLUICE GATE AS PER IS: 3042+

Introduction

These gates are Single faced rectangular or Circular Sluice Gates suitable for wall mounting on seating head of 15 Meter. These gates are suitable for seating head application only. The standard opening size of these gates is from 200 to 1200 mm. size of different shape with rising and non rising spindle. These are suitable for wall mounting.

Optional features

- Where small and medium volume of raw filtered, Storm water or sewage is to be controlled.

- For water supply drop of and purification work, sewage plants, drainage water, irrigation, canals. Hydro electric collection, aqua ducts and tail racks. These can be operated by manually hand wheel, with or without gears, pneumatically or with electrical actuators.

- For extension rod above 2 Meter long guide bracket are necessary to provide for spindle height for non rising spindle thrust bearing shall be provide. Yoke of frame for safe transmission while opening and closing the door.

- Painting specifications can be selected from Chart 2.

- Optional features & Accessories can be selected as per requirement.

- Manual lift is suitable for effort load less than 20 Kg.

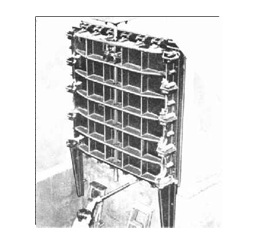

Fabricated Stainless Steel,IS: 4633 AWWA C: 561, C: 562, C: 563+

Introduction

These slide gates are single faced, consisting of fabricated open frame and slide. These are light weight gates embedded on wall or in channel useful in low pressure reservoir or tank hydroelectric water tank.

Optional features

- These gates are suitable for seating and non seating head. The gate leaf or operating member is rigid structure confirming suitable ribs in cross direction.

- The sluice gate seals are provided with rubber or metal led depending on the working pressure.

- Provision of adjustable wedges is used to reduce seal wear, while operation of slide gate couplings and stem guide are provided as per requirement according to operating height.

- The slide gates can be operated manually by hand-wheel with and without gears and mechanically by means pneumatic and electric actuators for operational ease depending on operating conditions and frequency.

- These slide gates can be provided with flush bottom wall mounted invert bottom arrangement.

- This gate can be self content with direct lifting arrangement fixed on gate frame.

Open Channel Sluice Gates Cast Iron / Mild steel / Stainless Steel / Aluminium+

Introduction

These gates are generally used in open channel of water or sewage. These gates are fixed between two parallel walls used to isolate the flow to and from the open channel. These are light weight, economical Gate assemblies for faster erection.

Optional features

- These sluice gates are suitable for seating and unseating water head.

- The important factor consider during design is the height of water in closed condition should be less than height of gates.

- These gates can be self content with operating head fixed on the gate frame.

- These gates can be provided with flush bottom wall mounted invert bottom arrangement.

- Depending on the operating pressure and operation frequency rubber seals, metal seals neoprene/ Natural / EPDM Rubber seals with rubber retaining bar are used.

- These gates are provided with Pin and Knuckle type stem connection for gate plates with spindle for rising spindle arrangement.

- For corrosion resistance, weather resistance, and saline water resistance suitable coating shall be adopted for long life.

WEIR GATES+

Introduction

Weir gates are down word operating sluice gates used in many treatment plants to control the effluent level on one side of the gate. These gates open when gate plate is moved in down word direction to flow the water top of plate.

Optional features

- The weir gates features with neoprene rubber seals mounted so as not to interface with water flow. This provides better sealing.

- UHMW (Ultra High Molecular Weight) Polyethylene seals are provided to reduce friction.

- These gates are provided with manual lifting provisions or electric motor, Hydraulic or Pneumatic Actuator as per requirement.

STOPLOG GATES+

Introduction

Stoplogs are generally used to isolate equipments such as pumps, screens, service gates for maintenance and repairs where absolute sealing out of water is not necessary.

Water front stoplogs are designed to suit industrial and domestic effluent environments to work against corrosion, ease of operation.

Optional features

- Stoplogs are open channel level controlling gates where single multiple logs (Beams) are inserted in channel. Logs can be of Mild Steel, Stainless Steel, Aluminium, Wood, HDPE

- Material and coatings are carefully selected to suit the requirements of environment such as saline water, alkalis and acidic water etc.

- Coatings available such as FRP Epoxy Zinc Galvanizing etc.

- Adjustable lifting beam can be provided. Chain Pulley crane can be used for beam or gate lifting.

- Seals can be mechanically fixed and replaced. EPDM neoprene rubber used as per requirements.

- These have low maintenance and low installation cost.

FIBRE REINFORCED PLASTIC (FRP) GATES+

Advantages

| Strong Weather-ability | Tough in strength | Long Life |

| Maintenance Free | High resistance to Corrosion | Strong Chemical Resistance |

Material of Construction

As per application FRP Gates are manufactured with FRP membrane for Gate plate & Gate Frame with stiffness & strength provided by MS/ SS etc as per requirements. Rubber Seals are provided with seal retainer bar.

Features

- Water seals available from Neoprene, Natural and EPDM Rubber for contacts mounted on gate plate & set for free movement with least leakages.

- Body of Sluice Gate i.e. Gate Plate, Gate Frame, Stiffeners, made in high strength FRP of Saline water compatible grade for better weather & chemical resistance.

- Strength backed by SS/ MS membrane with heavy duty weather & chemical resistance by FRP cast body membrane.

- Other varieties in features is available as per other sluice gate features & options as per our catalog in bottom closure spindle type, lifting mechanism, and coupling, stem cover, etc

SCREENS MANUAL, MECHANICAL FINE & RAKED+

Introduction

The screen is typically installed in a pumping station or at the inlet of sewage or water treatment plants. The retained solids are then extracted by means of a cable driven manual raking system which lifts the solids outside the channel and discharges into a hopper.

To prevent material too coarse from reaching the travelling band screens, bar screens may be used in two stages where the first screen with wider bar spacing remove bulky solids; a second bar screen with smaller bar spacing then remove debris still coarse enough to clog travelling band screens installed downstream for finer screening.

Filtration at the first stage of sewage water intake system is done by variety of bar screens. & then fine screens are provided for screening as per required sieve.

Varieties of Screens

- 1. Fine Screens- Generally distance between two bars is

- 2. Medium Screen- Generally distance between two bars is

- 3. Coarse Screen- Generally distance between two bars is

- Wedge Type Bar Screen: Easy to clean lesser maintenance.

- Raked/ Linear Type mechanical Screens-

The smooth running, endless track system employs a gear-driven cleaning rake to carry screenings from the submerged bar rack to a discharge chute for removal without the use of chains, sprockets, cables or any underwater moving parts.

Applications - STP headwork: protect downstream equipment, Pumping

stations; flood control; Water intake for remove large debris; Ideal for both municipal

and industrial use.

Benefits - Above water operation, No submerged moving parts; Flexible

& customized design, Heavy duty, wide range, Positive screening discharge.

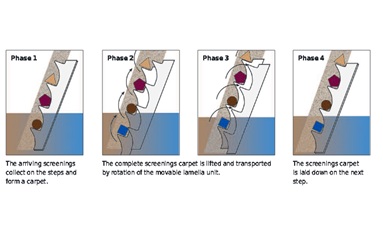

Mechanical Fine Screens/ Step screens+

Introduction

The step screen consists of a series of stationary and mobile steps alternating with each other. As the effluent flows through the step screen, a screening mat develops along the surface of the screen. The mobile steps progressively lift the mat of solids along the inclination of the screen. On reaching the top of the step screen, the solids are discharged by gravity into a screw conveyor or similar device. The low-inclination angle ensures that a screening mat is retained continuously during the entire operation and prevents the roll down encountered in steeper screens.