Select And Customize

FACTORS BEFORE SELECTION+

FACTORS BEFORE SELECTION

- 1. Flow material to decide Gate type, Material of construction, Coating requirements etc

- 2. Size of Gate according to opening at well or channel etc.

- 3. Direction of flow and

- 4. Fluid head on both sides

- 5. Mounting Conditions- wall/ channel/ pipe/ thimble

- 6. Distance of operating head to Gate

- 7.Operation frequency & operation area height

- 8. Method of operation

VARITIES OF OPTIONS ARE TO BE CONSIDERED BEFORE CHOOSING SLUICE GATE+

VARITIES OF OPTIONS ARE TO BE CONSIDERED BEFORE CHOOSING SLUICE GATE

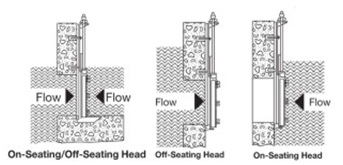

- a. Flow Direction

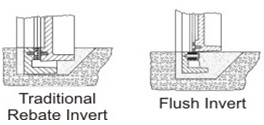

- b. Bottom sealing

- c. Type of Mounting

- d. Spindle Movement

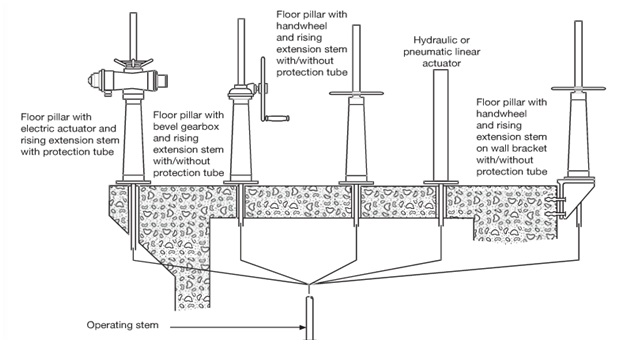

- e. Mounting Position of lift mechanism

- f. Method of operation ( see last page)

- g. Extra fittings

On Seating head - Pressure forcing the door onto the frame Off seating head- Pressure forcing the door away from frame Seating/ off-seating Head- Pressure forcing the door from both sides of frame

Traditional rebate invert type. Flush invert Available with resilient sealing strip to produce laminar flow, improved hydraulics, efficiency

Depending on availability of surface where gate is to be mounted.

a. Wall Mounting: Flat Back- Gate frame fixed with wall directly with foundation nut bolts. Thimble Mounted: When high sealing pressure is specified, careful consideration is needed for fixing the gate in the structure. Gates fixed on wall with wall thimble. Ease of gate installation & removal for re-sitting or cleaning. Spigot Mounted: When high sealing pressure is specified, careful consideration is needed for fixing the gate in the structure. Here gates frame is with spigot back. Once fixed in wall these cannot be removed for maintenance.

b. Channel Mounting: Sluice Gates can be mounted in open channel. These channels are grouted with Gate Frame.

Rising Spindle- non rotating spindle. Threaded Nut is provided on hand-wheel. Here spindle rises above while opening gate & lowers when gate closes. Non-rising spindle- Rotating spindle. Threaded stem nut provided on Gate plate. Here spindle does not move in vertical direction. These are used where limited head room is available.

Platform mounted Head: Used where distance between gate & platform is more than 2 times. Flange mounted Used where Platform is not available off the wall. Self contained are used where the operating platform is below fully opened position gate lavel.

Manual: Direct drive, Geared- Worm/ Bevel Motorized: Pneumatic/ Hydraulic/ Electrical Actuated.

Stem extensions / coupling (as plain & screwed) Guides Coatings & linings- Epoxy , Rubber, FRP etc Shaft cover/ Hood- Galvanized MS pipe/ Polycarbonate

PAINTING SPECIFICATION & BENIFITES+

DEPENDING ON THE FLUID CONDITIONS FOLLOWING PAINTING SPECIFICATIONS IS USED

| Normal or Fluid water | One Coat of Red Oxide primer and finish coat of bitumen paint. |

|---|---|

| Sewage water application | Primer of Epoxy Red Oxide or Epoxy Zinc with finish coat of coal-tar epoxy. |

| Alkaline water condition | One Coat of Red Oxide primer and finish coat of bitumen paint. |

| Corrosive and Acidic effluent | primer of epoxy red oxide with FRP coating with finish coat of coal-tar epoxy. |

COMPARE MATERIAL- CI TO MS TO SS TO ALUMINIUM+

Compare material- CI to MS to SS to Aluminium

| Cast Iron Sluice Gates | Fabricated S.S. / Aluminium/M.S. Sluice Gates |

|

|

|---|

VARIETIES OF OPERATIONG METHODS+